- Predictive and corrective tests and inspections for the mining, oil and gas industry, in annual, semi-annual, monthly or daily periods, according to the characteristics of the industry and machinery that make up the plant, as well as recommendations for industrial maintenance.

- Inspections of hydraulic and thermal generator installations.

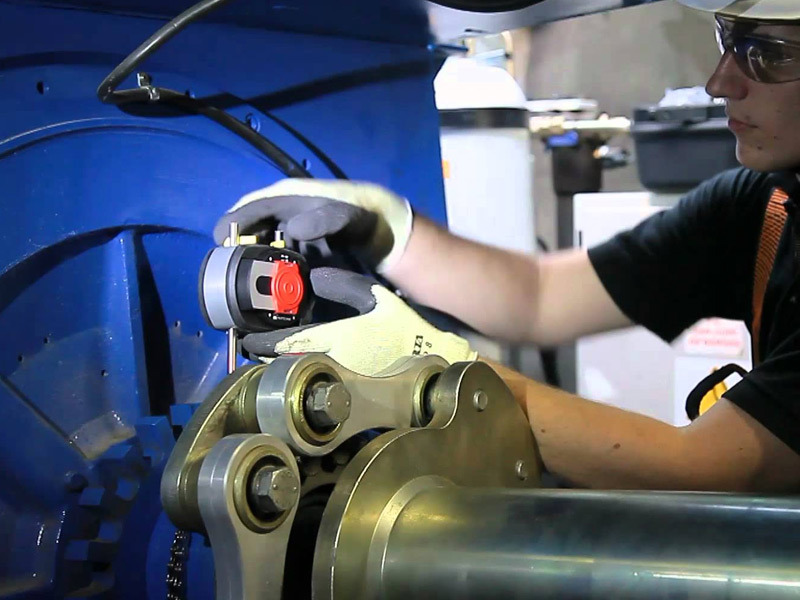

- Inspections and alignment service, vibrational analysis, IN SITU balancing, mechanical and electrical checks, corrections, commissioning of hydraulic and thermal generating units.

- Evaluation and structural design of heavy machinery. The software of analysis by finite elements and the criteria that the Engineering executes and evaluates, for the application of the pertinent Construction Codes.

- Studies of the industrial machinery and Evaluation of the operation of the processes are carried out by by experienced professional and technical staff.

We have personnel with qualification level I - II - III (SNT-TC-1A) in the various specialties of NDT and predictive maintenance, with work experience in gas, manufacturing, mining, energy and oil industry.

SPECPRO has the capacity to mobilize groups of personnel and teams to meet the needs of any Project, stop or interruption - planned or unforeseen.

- Alignment of Axes with laser equipment and Total Station.

- IN SITU Rolling

- Static Balancing.

- Training at Technical Associates of Charlotte -USA

- Motor Rotors and Electric Generators.

- Heavy Machinery Transmission Shafts.

- Mining Mills.

- Fans up to 2 meters in diameter.

- Industrial, Oil and Mining Pumps.

This thermographic service has been applied in a timely manner in the electrical sector and facilities for: machinery, electrical panels, etc. To minimize the risk of equipment failure and their consequences.

Test of tightness, detect leaks in pipes, couplings, connectors and accessories and, therefore, improve the energy efficiency of compressed air systems.

Inspection in the measurement of hardness applied in welding repairs, structures of heavy machinery, cauldrons among others.

Inspection by:

- Currents of Eddy.

- Magnetographic essays.

Thickness Measurement Services:

- Inspections in Cauldrons, Tanks, Pipes, Pipeline.

- Measurement and Monitoring of elongations.